Swiss Innovation

Having won “Best of the Best” Red Dot 2023 design award, the Cutting Edge Technologies design team had the privilege to discuss its approach to design with the Red Dot organizers, particularly as related to SWISSORS® Mark II.

Target users for SWISSORS® are professional tailors, sewing enthusiasts, fashion designers, technical textile cutters, upholsters, and anyone else simply looking for a good pair of scissors to have at hand.

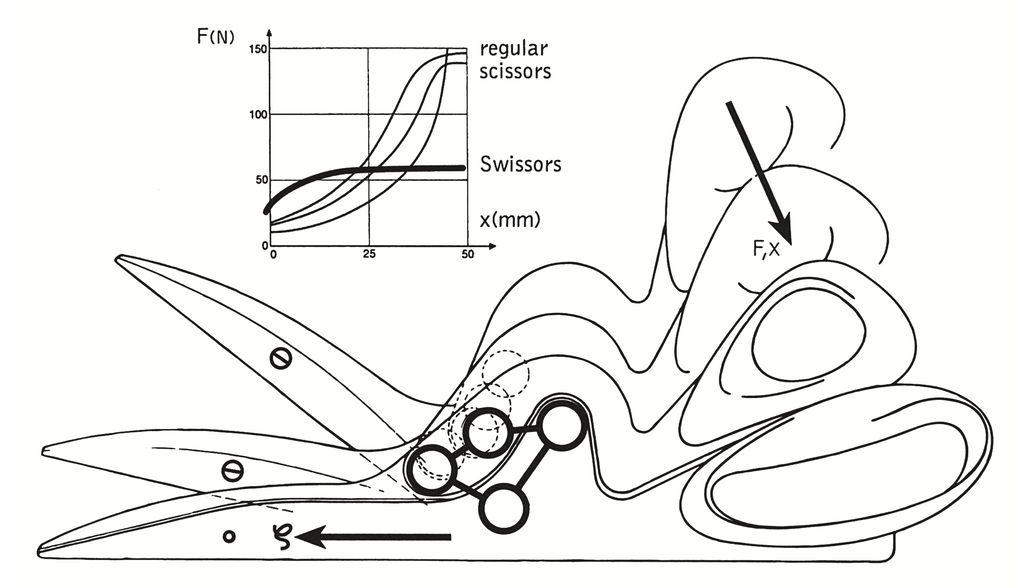

The main goal in designing SWISSORS® was to eliminate the compromise accepted in the use of conventional tailoring scissors where the single pivoted blades elevate the material being cut from the cutting surface making it harder to cut with precision. Our solution with a four-bar-linkage addressed the basic problem but – as usually is the case – it also introduced new problems. One of those was the use of needle bearings in the four-bar-linkage that prevented dismantling the scissors for sharpening. Thus, the replaceable blades of SWISSORS®.

The conventional approach to ergonomics limited to shaping the handles of scissors does not address the fundamental problems of a single pivot scissors type. The center of gravity of the whole scissors moves up and down, which in the case of classical, heavy cast metal scissors pains and tires the thumb on the way up. On the way down hand force required for cutting with the tips of the scissors is much higher than closer to the pivot, yet the tailors tend to use the tips to avoid elevating the material from the table. The largest component of SWISSORS® supporting the lower blade remains flat on the table and the four-bar-linkage was designed to keep the hand force nearly constant for the full length of the cut.

The rapid development of technical composites allowed their use for applications traditionally reserved for metals. Injection molding of the main components of SWISSORS® with the highest-grade 40% carbon-reinforced polyamide provides sufficient stiffness to support the blade inserts made from hardened stainless steel with titanium nitride-coated cutting edges. The coating extends the life of the blades by at least a factor of ten.

At Cutting Edge Technologies we always start by looking for an engineering answer to the question that Clayton Christensen formulated in his studies and writings on innovation as a “Job to do”. It may be related to existing products that always have shortcomings or something that needs to be created from scratch.

Designing with the appreciation of beauty in human-made objects, be it in manufacturing, architecture, or even art, particularly in sculpture, should never impede the engineering task of getting the “Job done”. SWISSORS® Mark II, hopefully embodies these principles.